Application Case of an Innovatively Designed Timing Belt in Photovoltaic Manufacturing Equipment

Side Curved Design, Scratch-Proof, Anti-Deviation, Noise-Reducing Timing Belt

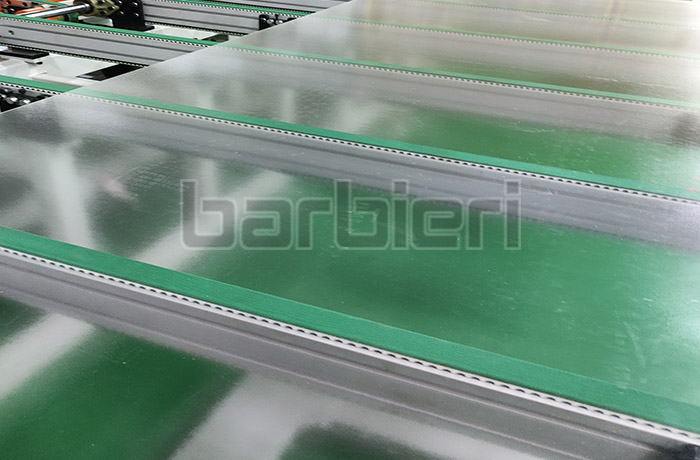

The efficient and stable operation of a PV module production line plays a crucial role in improving production efficiency and ensuring product quality. As a core component of the equipment's transmission system, the performance of the PV module production line timing belt directly affects the overall operation of the equipment. Barbieri leveraging years of technological accumulation and industry experience, has meticulously crafted a new double-sided green fabric PV module production line timing belt with a side curved design. Its superior performance and reliable quality have made it an ideal choice for photovoltaic industry equipment.

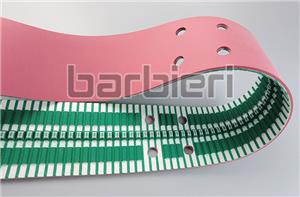

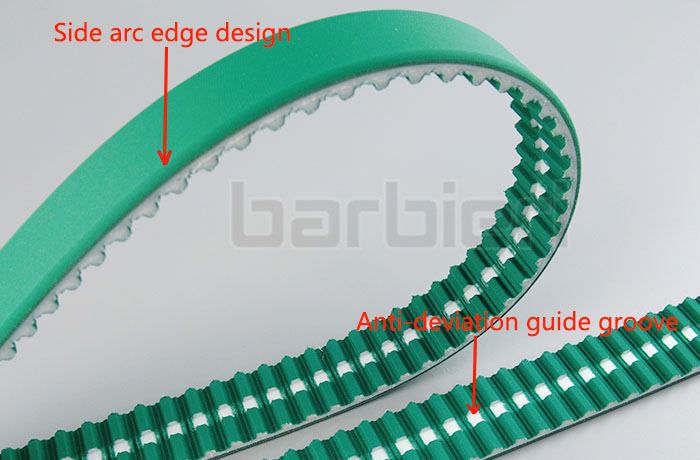

This innovative design breaks with tradition and meets the stringent requirements of photovoltaic manufacturing. The PV module production line timing belt features a side curved design, with curved corners on both sides ensuring a smooth, burr-free edge. The tooth surface machining positioning guide groove, combined with the matching timing pulley with guide ring, effectively prevents the timing belt from deviating during transmission.

The double-sided fabric timing belt, with its curved sides, is made of high-quality polyurethane substrate with a high-strength steel wire core skeleton. The green cloth covering the toothed surface significantly reduces noise and provides excellent properties such as anti-slip, anti-scratch, anti-deviation, high strength, tear resistance, and wear resistance. It is precisely matched to the high-precision production scenarios of the photovoltaic industry, providing a stable and reliable transmission solution for key processes such as silicon wafer cutting, cell welding, and module testing.

As a professional timing belt manufacturer, Barbieri understands the importance of product quality to its customers. During the production process, it strictly adheres to standards and industry specifications for quality control. Our company possesses advanced production and testing equipment to test various performance indicators of the timing belts, ensuring that all products meet high-quality standards.

To meet the diverse needs of our clients, we manufacture various types of PV Manufacturing Equipment Timing Belts, Double-Glass Solar Modules Timing Belts, Solar Panel Conveyor Belts, Solar Photovoltaic Conveyor Belts, Glass Loading & Placement Machine Timing Belts, Cutting Layup Machines Timing Belts, and Trimming Framing Machines Timing Belts. We also offer customized manufacturing services for various specifications (tooth type, length, width, etc.)

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt