Polyurethane Self-tracking Timing Belt

-

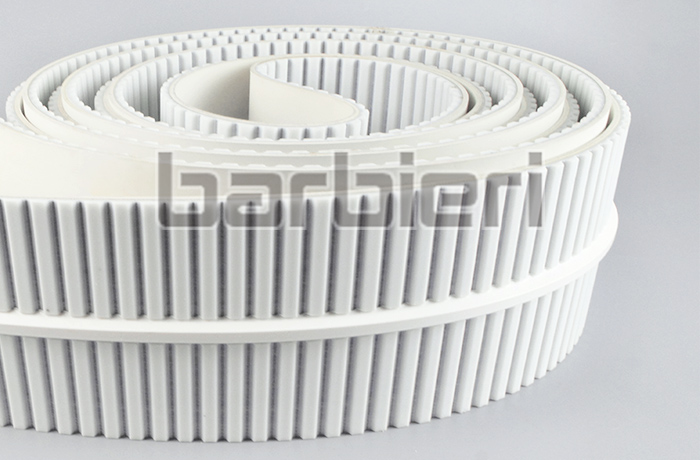

BAT10 Kevlar Core Timing Belt

Barbieri® BAT10 Kevlar core timing belt has a unique crescent tooth design. The timing belt has a Kevlar core inside, which is light and flexible. The crescent tooth design increases the contact area of the tooth surface, which can provide better power transmission and meshing effect.

Email Details -

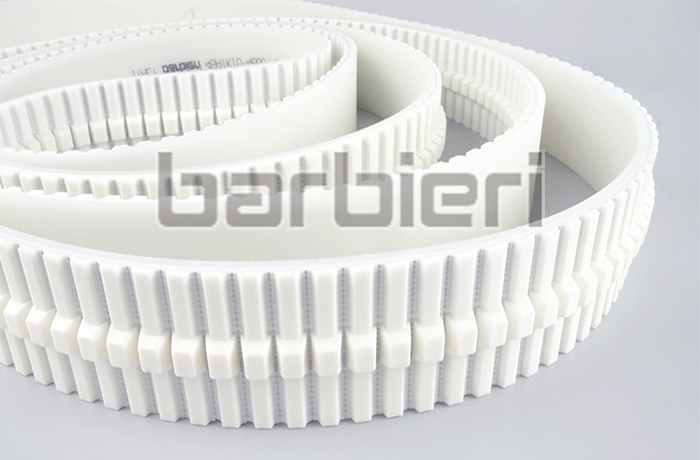

BATK10 Self Tracking Timing Belt

Barbieri® BATK10 Timing belt with integrated guides on the tooth surface, special crescent tooth shape for noise reduction and self-guide rails to prevent deviation, surface can be covered with cloth as required, back with various coverings. Perfect self-tracking timing belt, using timing pulleys with tracking guide grooves, accurate belt tracking can be achieved without pulley flanges.

Email Details -

ATK10-K13 K6 Self Tracking Timing Belt

Barbieri® ATK10-K13 K6 self-tracking timing belt is made of thermoplastic polyurethane, with high-strength steel wire core embedded inside. Kevlar core can be selected. High strength, low maintenance, high-precision transmission performance make it an ideal choice for automation equipment.

Email Details -

Timing Belt With Tracking Guide

Barbieri® Timing Belts Tracking Profile Correctly guide the timing pulley rails, made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

The integrated guide strip timing belt is formed by a mold. Its function is to make the timing belt run accurately on the equipment, prevent longitudinal or lateral deviation, and the tooth surface guide strip coincides with the synchronous gear teeth, which has the advantages of more accurate operation and greater load force. -

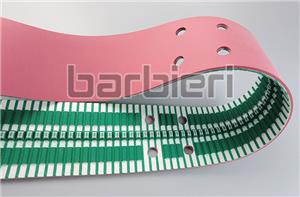

Timing Belt With Welding PVC Tracking Central Guide

Barbieri® synchronous belt with PVC tracking central guide : made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

The tooth surface of the timing belt and the guide bar have the function of positioning and guiding. Its function is to make the timing belt run accurately on the equipment and prevent longitudinal or lateral deviation.