Minimum bending diameter of timing belt for smooth turning

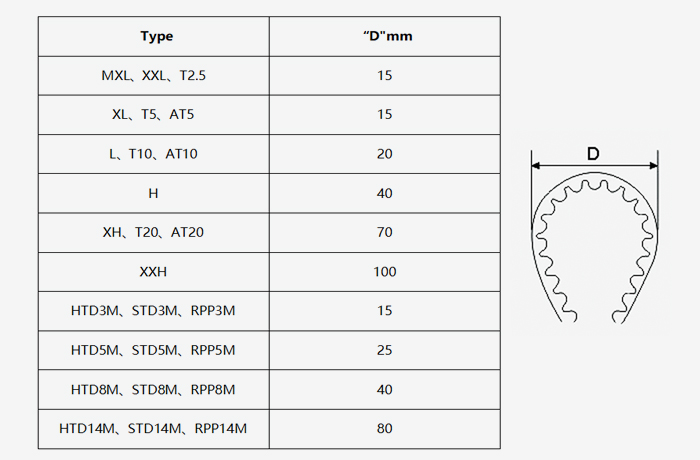

The minimum bending diameter of the Timing belt refers to the minimum bending radius that the timing belt can pass smoothly during normal operation. It is an important parameter in the design and application of timing belts, and is of great significance to ensure the normal operation of the timing belt and extend its service life.

When designing and selecting a timing belt, its minimum bending diameter must be fully considered to ensure that the timing belt can operate stably in various working environments and achieve the expected transmission effect.

The above is the reference value of the minimum bending diameter of the timing belt without additional covering layer. When the timing belt is attached with different covering layers, the minimum bending diameter allowed for different types of Timing belt with backing will change accordingly. Please consult our technical department for details.

In practical applications, when the timing belt needs to be bent, its internal tooth structure will be deformed to a certain extent. If the bending diameter is too small, it will cause excessive deformation of the tooth structure of the timing belt, affecting the accuracy and stability of the transmission. The minimum reverse bending radius of the timing belt needs to be comprehensively evaluated. Engineers need to select the appropriate timing belt type and specifications based on actual transmission needs and environmental conditions to ensure that the transmission system can work stably and reliably.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt