What are the anti-static treatment methods for polyurethane timing belts?

Polyurethane timing belt is a synchronous transmission accessory commonly used in mechanical transmission systems. For places where static electricity is required, such as circuit board production lines, chemical industry, coal and other industries, equipment transmission and conveying systems must meet anti-static requirements due to environmental issues. In order to help customers solve such problems, polyurethane timing belts have achieved antistatic properties. Antistatic timing belts the following are common antistatic treatment methods:

1. Spray a layer of anti-static spray agent on the surface of the PU timing belt, which can effectively release the static charge on the surface of the timing belt. The spray thickness and spray interval of the anti-static spray agent should be reasonably controlled to ensure that it can effectively release the electrostatic charge.

2. The surface of the timing belt is coated with an antistatic coating, which can effectively suppress the accumulation of static charges on the surface of the timing belt. The thickness and resistivity of the antistatic coating are reasonably controlled to ensure that it can effectively suppress static charges. build up.

3. The surface of the timing belt is coated with a conductive coating, which can release the static charge on the surface of the timing belt to avoid the accumulation of static electricity. The thickness and resistivity of the conductive coating are reasonably controlled to ensure that it can effectively release static electricity. load.

4. Install some conductive parts on the surface of the timing belt, such as grounding wires, metal sheets, etc. These conductive parts can release the static charge on the surface of the timing belt to the ground, thereby avoiding the accumulation of static electricity. The number and position of the conductive parts should be reasonable. Control to ensure that it can effectively release static charges.

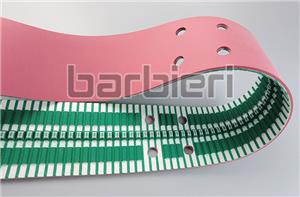

5. Add an antistatic polyurethane mixture, which is a special conductive polyurethane mixture, to the belt body of the timing belt. Add an antistatic cloth layer to the tooth surface and back of the timing belt to achieve the antistatic effect.

In summary, polyurethane timing belts generate static electricity during use, and anti-static treatment measures must be taken. Different application scenarios may have different anti-static requirements for polyurethane timing belts. Therefore, when selecting anti-static treatment methods, it is necessary to After comprehensive consideration of the specific application scenarios and needs, no matter what anti-static treatment method is adopted, the anti-static performance of the polyurethane timing belt needs to be regularly tested and maintained to ensure its long-term stable operation. If you need it, please consult our Technical Department.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt