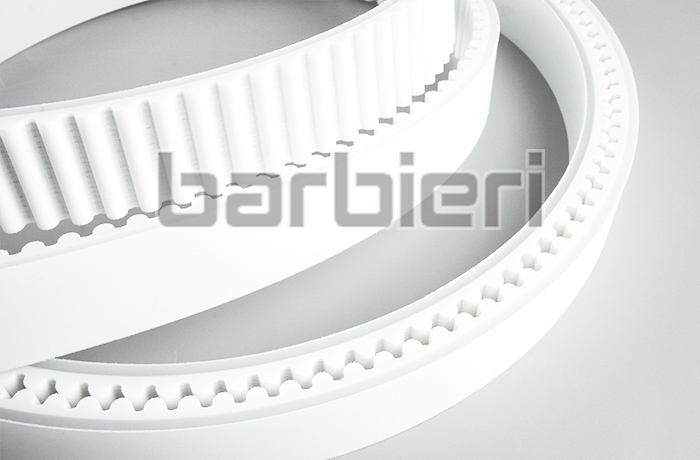

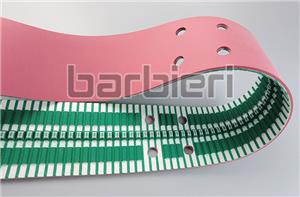

Timing belt tooth and back with polyamide fabric

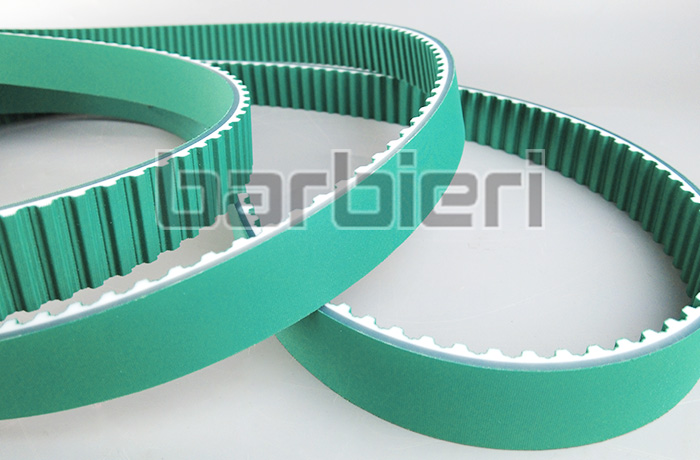

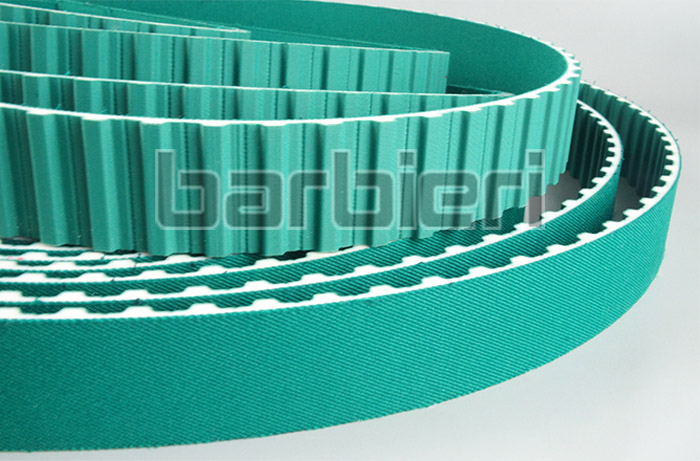

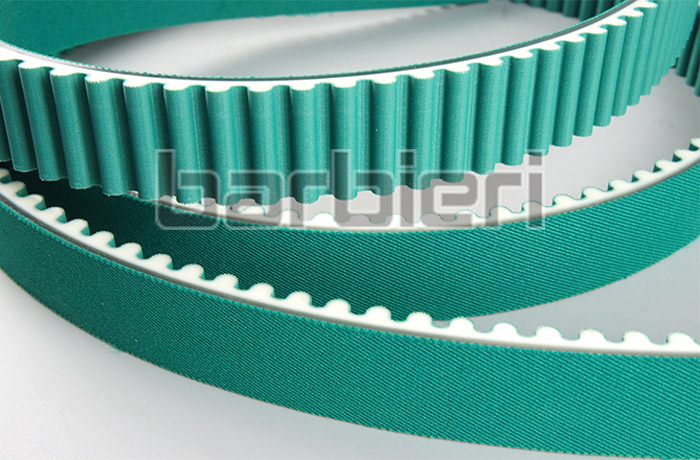

Barbieri® Timing belt with PAZ -PAR: PU timing belt tooth surface plus nylon surface can effectively reduce the friction coefficient, enhance the meshing of the belt and pulley, reduce noise and vibration; add nylon surface on the back can effectively prevent slipping, pollution, and most oils Protect product delivery, etc. Usually a layer of PU is added to the back of the timing belt to increase the surface friction of the timing belt, the tensile strength of the timing belt, and prolong the service life.Double-sided green cloth timing belts have been widely used in photovoltaic industry component transportation and automatic assembly lines.

The timing belt tooth and back are made of thermoplastic polyurethane with an embedded high-strength steel wire core. The PU layer in the middle of the timing belt increases tensile and tear resistance, effectively extending its service life. The PU adhesive is integrally molded with the base belt, ensuring a very strong bond. This integrated molding technology eliminates concerns about delamination, making it a very popular timing belt among users.

Timing belt with PAZ-PAR: Depending on different customer needs, the timing belt can be made with white, green, or black fabric. Tooth type, length, width, etc., can be customized.