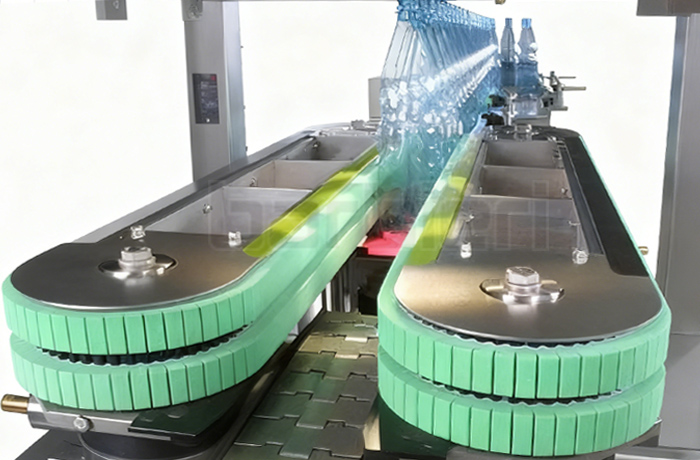

Bottle Inspection Machine/Bottle Clamping Machine Timing Belts & Heuft EBI Machine Application Belts

The core function of the timing belt combined with sponge is to buffer, dampen, seal, protect fragile products, and ensure stable transport. Common types include green sponge timing belts, black sponge timing belts, and blue cloth sponge timing belts. Different working conditions are selected according to different material densities. High-density sponge has high hardness, fast rebound, strong wear resistance, and is not easily deformed, making it suitable for contact with steel or glass. Low-density sponge is soft, has good cushioning, large compression capacity, and strong adhesion, making it suitable for contact with thin plastic tubes and other light objects. It is widely used in labeling machines, bottle inspection machines, bottle clamping machines, and special belts for beer production lines. Barbieri manufactures various types of sponge timing belts (Full Bottle Can Inspection Timing Belt) to meet the special needs of different brands of machinery and equipment in the bottle inspection machine, bottle clamping machine, and beer industry. (For example, Kroens, Heuft, Miho David machines)

The Green Sylomer timing belt, with its cross-cutting process, is a dedicated timing belt designed specifically for Heuft EBI machines. It is also ideal for inspection, conveying, and packaging applications in the food and beverage industry, providing precise synchronization and positioning during automation.

Heuft EBI Belt is made of high-quality polyurethane material with an embedded high-strength steel wire core and a high-density sponge cover. It features rapid rebound, high abrasion resistance, and resistance to deformation, ensuring durability and reliability.

The polyurethane timing belt features a specially processed sponge with uniform cross-cutting, ensuring efficient movement and smooth operation without slippage or misalignment. It facilitates bottle tipping, has excellent resilience, high density, and offers various sponge thicknesses and colors. Custom manufacturing is available based on provided specifications (tooth type, length, width, etc.).

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt