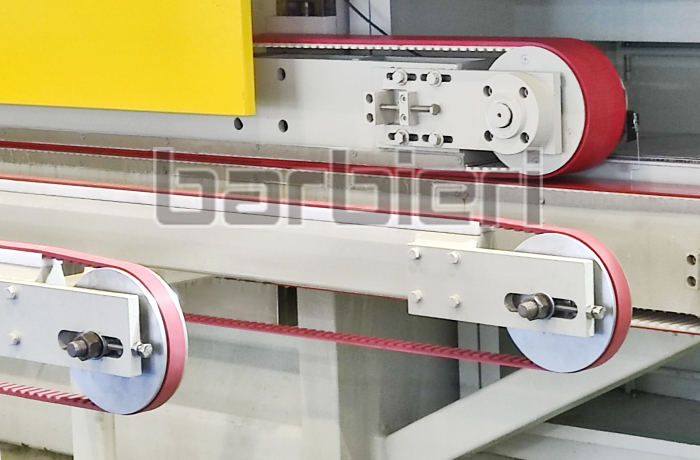

Synchronous belt and synchronous wheel installation method

The first step is to turn off the power, then put down the protective cover, and loosen the mounting bolts of the motor. Move the motor to make the timing belt slack enough so that the timing belt can be removed without prying. Never pry off the timing belt.

The second step is to select the appropriate timing belt to be replaced later.

The third step is to remove the old timing belt and check for abnormal wear, which may mean that there is a problem with the design or maintenance of the transmission device.

The fourth step is to check whether the synchronous pulley has abnormal wear or cracks. If the wear is excessive, the pulley must be replaced.

Step 5 Check whether the pulleys are in line symmetry. Synchronous belt pulleys are linearly symmetrical to the operation of the transmission belt, especially the operation of the synchronous belt transmission device.

Step 6 Check the rest of the transmission components, such as the symmetry of the bearing and the shaft sleeve, durability and lubrication, etc.

Step 7: To clean the timing belt and timing belt wheels, wipe the rag with a little non-volatile liquid. Soaking in detergent or scrubbing the timing belt with detergent is not advisable. In order to remove oil and dirt, it is obviously not advisable to scrape with sandpaper or sharp objects. The timing belt must be kept dry before installation and use.

Step 8 Install a new timing belt on the timing belt wheel, never pry or use excessive force.

Step 9 Tighten the center distance of the transmission device until the tension measuring instrument detects that the tension of the timing belt is appropriate. Turn the driving wheel several times by hand and re-measure the tension.

Step 10 Tighten the mounting bolts of the motor to correct the torque. Since any change in the center distance of the transmission device during operation will result in poor performance of the timing belt, it is important to ensure that all transmission components have been tightened.

Step 11 Start the device and observe the belt performance, check whether there is abnormal vibration, and listen carefully for abnormal noise. It is best to turn off the machine and check the condition of the bearing and motor: if it feels too hot to the touch, it may be because the belt is too tight, or the bearing is asymmetrical or incorrectly lubricated.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

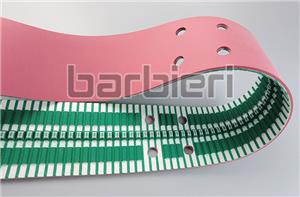

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt