The difference between polyurethane timing belt and rubber timing belt

Polyurethane timing belts and rubber timing belts are both widely used industrial belts. They perform well in many applications and have their own advantages and differences. When selecting, the appropriate timing belt type should be selected based on the specific working environment and equipment needs.

1. Material difference:

Polyurethane timing belt: Made of polyurethane material, the rope core is generally made of galvanized steel wire rope core (or stainless steel wire rope core or Kevlar rope core).

Rubber timing belt: Made of rubber material, the rope core material is fiberglass rope core, and the tooth surface is protected by nylon elastic cloth.

2. Hardness difference:

Polyurethane timing belts are generally around 92 degrees Shore; rubber timing belts are generally around 80 degrees Shore.

3. Differences in temperature resistance:

Normal operating temperature of polyurethane timing belt: -10℃ to +60℃ (can withstand up to +80℃ in a short period of time);

Normal operating temperature of the rubber timing belt: -35°C to +80°C (can withstand up to +115°C in a short period of time).

4. Feature differences:

Polyurethane timing belts are more wear-resistant than rubber timing belts and are more resistant to chemicals such as acids and alkalis.

The polyurethane timing belt has good wear resistance (no powder will fall off due to friction); the rubber timing belt will easily shed powder when it is rubbed.

5. Application differences:

Due to its soft and elastic properties, rubber timing belts are often used in situations that require shock absorption and buffering. They are mainly used in agricultural machinery, mechanical transmission, automobiles, printing, labeling, folder-gluing machines, etc.

In contrast, polyurethane materials have extremely high wear resistance and durability, do not shed powder during friction, and can run smoothly under high loads. This characteristic makes polyurethane timing belts an ideal choice for many applications. It is more suitable for clean production, medical industry, food industry, as well as automation equipment, packaging machinery, textile machinery, glass machinery, ceramic machinery, etc.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

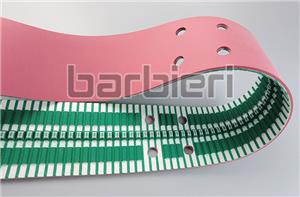

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt