The structure and working principle of the timing belt lifter

Timing belt lifter is a lifting device that uses the timing belt as the transmission medium. With its high efficiency, stability and precision, it plays an important role in many industrial fields. It is worth noting that the performance of the timing belt lifter depends largely on the quality and precision of the timing belt and timing pulley. High-quality timing belts and timing pulleys can provide higher transmission efficiency and longer service life, thereby reducing maintenance costs and failure rates.

The timing belt lifter is mainly composed of the following parts:

1. Power system

It includes a motor, a reducer and a transmission control module, in which the motor (AC or DC) provides driving force and the reducer converts high-speed rotation into high-torque output. Some models are also equipped with a disc brake motor to achieve precise start-stop control.

2. Timing belt and Timing pulley

As the core transmission component, the timing belt and the timing pulley mesh to transmit power to ensure the synchronization of multi-channel lifting. The timing pulley is usually made of high-strength materials and needs to be adjusted with a tensioning device to adjust the transmission stability.

3. Lifting components

Lifting platform/pallet: a rigid structure that directly bears the load, and is vertically guided by guide rails or guide wheels.

Guide rail system: includes standard section guide rail frame, guide wheels and limit devices to ensure the accuracy of the lifting trajectory and anti-deviation capability

4. Auxiliary system

Control system: integrated PLC, touch screen and safety circuit to achieve multi-axis synchronous control and emergency braking

Safety devices: such as anti-fall safety device, overload protection and mechanical limit blocks to meet safety standards

Working principle of timing belt lifter

1. Power transmission and synchronous control

The motor drives the driving wheel to rotate, and transmits power to the driven wheel through the toothed meshing of the timing belt and the timing pulley, driving the lifting platform to move.

Multiple sets of timing belts and timing pulleys ensure strict synchronization of multiple lifting points.

2.Motion stability guarantee

The guide rail system constrains the movement trajectory of the lifting platform, and the guide wheel or slider reduces friction to avoid deflection.

The closed-loop control system monitors the position deviation in real time and dynamically adjusts the motor speed to correct the error.

3. Error compensation and safety redundancy

The elastic material of the timing belt (such as polyurethane), that is, the polyurethane timing belt, can slightly deform to compensate for installation errors.

Safety devices (such as mechanical limiters and fall arresters) trigger braking when overspeeding or overloading to prevent accidental falls.

- Polyurethane Timing Belt

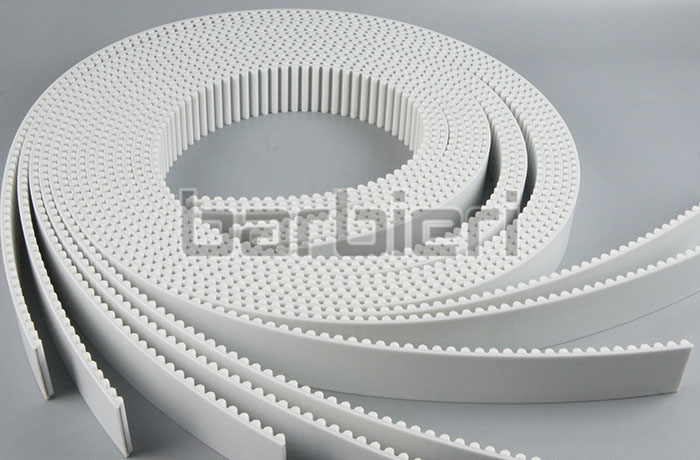

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

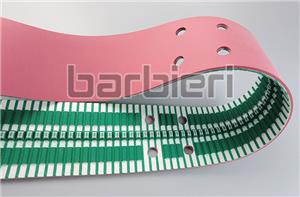

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt