Timing belt failure analysis guide &Corrective action

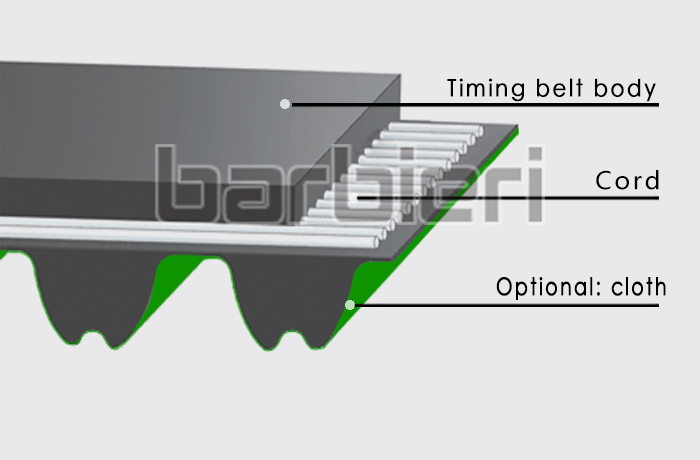

Timing belt is made of galvanized steel wire, stainless steel wire or Kevlar rope core as the strength layer, and is covered with polyurethane annular timing belt or open-end timing belt . The inner circumference of the belt is toothed and meshes with the timing wheel of the same tooth shape. When the timing belt is driven, the transmission ratio is accurate, the force on the shaft is small, the structure is compact, the oil resistance is good, the wear resistance is good, and the anti-aging performance is good.

Timing belt structure:

During the use of timing belt, some common problems will occur, such as timing belt breakage, excessive belt wear, excessive tooth wear, tooth shearing, belt longitudinal cracks, belt elongation, cracks on the back of the belt or belt softening, running The noise is too loud. In this regard, we have summarized the causes and solutions of common problems in the use of timing belts:

| DAMAGE | CAUSE | REMEDY |

Belt breakage | 1.Over load | Check design, choose correct belt width |

| 2.The inertia of the pulley is too much | Choose correct pulley | |

| 3.Pulley diameter too small | Modify design of pulley mesh teeth | |

| 4.Over initial tension | Adjust initial tension | |

| 5.Belt folded or twisted | Be careful of stock/transport/installation | |

| 6.Over impact load | Prevent accident,modify design | |

7.Belt run off over pulley flange | Adjust alignment and check pulley flange | |

| 8.Particles drop in arranger | Clean and check protective cover | |

Belt side abrasion | 1.Bad pulley alignment | Adjust alignment |

| 2.Bearing hardness under request | Increase hardness and be sure of fixing | |

| 3.Pulley flange bended | Amend or change flange | |

| 4.Pulley flange roughness | Amend or change flange | |

5.Belt touches protective cover or support frame | Check protective cover or support frame | |

Belt tooth abrasion | 1.Over load | Check design, choose correct belt width |

| 2.Preload too much | Adjust preload | |

| 3.Pulley tooth roughness | Check and adjust roughness | |

| 4.Pulley radial run-out | Check and adjust radial run-out | |

| 5.Dust or sand | Clean and check protective cover | |

| 6.Violent vibration | Adjust construction or use viration damper | |

| 7.Too much dirt drops in arranger | Clean and check protective cover | |

Belt tooth bottom abrasion | 1.Over load or over impact load | Check design |

| 2.Preload too small | Adjust preload | |

| 3.Pulley diameter too small | Increase pulley diameter | |

| 4.Temperature too high / oil or particles drop in | Change temperature and use protective cover | |

| 5.Stop by accident, load increases suddenly | Check equipment and prevent accident occurs again | |

Belt longitudinal breakage | 1.Belt run off pulley | Adjust alignment |

| 2.Belt run off over pulley flange | Adjust alignment and check flange | |

| 3.Belt run on flange when installing | Be careful of installation | |

Belt elongation | 1.Bearings improper installation, center distance decrease in operation | Be careful of installation/modify design |

| 2.Belt tensile layer loose | Change belt | |

| 3.Tension pulley loose | Check tension pulley,be careful of installation | |

| 4.Pulley abrasion | Change pulley | |

| 5.Over load | Check design, amend belt width | |

| Belt cracking or become soft | 1.Temperature is too high | Change temperature |

Abnormal noise level | 1.Over load | Check design |

| 2.Over preload | Adjust preload | |

| 3.Bad pulley alignment | Adjust alignment when installing | |

| 4.Belt wider than pulley diameter | Check design | |

| 5.Belt and pulley mesh improperly | Check belt and pulley |