What are the main parameters of industrial timing belts?

What are the main parameters of industrial timing belts?

1. Timing belt length

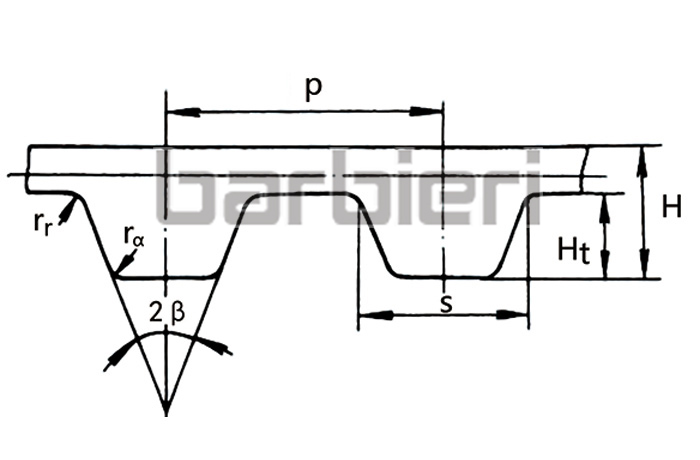

When the synchronous belt is working, the length of the center line of the bearing rope should remain unchanged, so this center line is called the pitch line of the timing belt, and the perimeter of the pitch line is used as the nominal length of the belt, which is called the pitch line length. In synchronous belt drive, pitch line length is an important parameter.

2. Timing belt pitch

The approximate length of the corresponding points of two adjacent teeth of the synchronous belt measured along the pitch line is called the pitch of the synchronous belt. The pitch of the belt determines the size of each part of the synchronous belt and the synchronous pulley teeth. The larger the pitch, the larger the size of each part of the belt, and the higher the bearing capacity. Therefore, the belt pitch is the most important parameter of the synchronous belt. In the pitch system timing belt series, the models of timing belts are distinguished by different pitches. During manufacture, the belt pitch is controlled by casting molds.

3. Timing belt tooth root width

The distance between the intersection of the tooth profile on both sides of a belt tooth and the bottom profile of the tooth root is called the tooth root width of the belt, expressed in s. The larger the tooth root width of the belt, the stronger the shearing and bending resistance of the belt tooth, and the correspondingly larger cutting load can be transmitted.

4. The tooth root fillet of the timing belt

The size of the tooth root return angle radius rr is related to the stress concentration degree of the tooth root when the tooth is working. The large radius of the tooth root fillet can reduce the stress concentration of the tooth and improve the bearing capacity of the belt. However, the radius of the tooth root return angle should not be too large. If it is too large, the effective contact area when the belt tooth meshes with the gear tooth will be small, so an appropriate value should be selected in the design.

5, with tooth tip fillet radius eight

The size of the rounded corner radius of the toothed tooth will affect whether the tooth will be generated from sand when the toothed tooth meshes with the gear tooth. Because in the timing belts drive, the meshing of the belt teeth and the pulley teeth is a kind of fitting for the non-conjugated tooth profile. Therefore, when the belt tooth enters or exits the meshing, the top corner of the toothed top and the top of the gear tooth will inevitably exceed the overlap, resulting in interference and wear of the belt tooth. Therefore, in order to enable the belt teeth to enter and exit meshing smoothly, and reduce the wear of the top of the belt teeth, a larger tooth top fillet radius should be used. However, like the root fillet radius, the tip fillet radius should not be too large, otherwise the effective contact area between the belt teeth and the gear teeth will be reduced.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

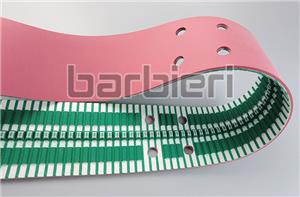

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

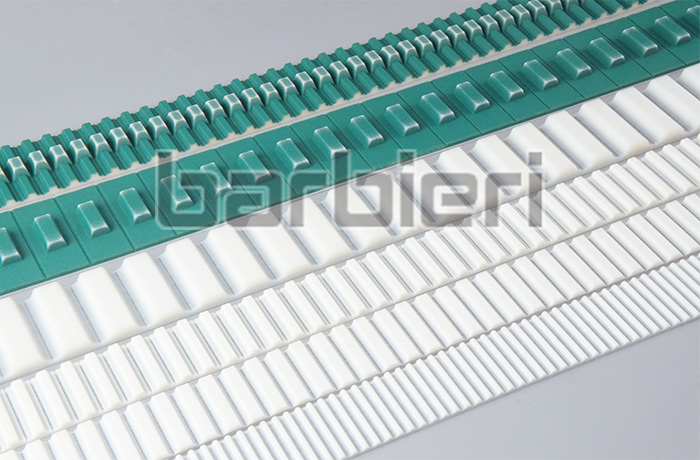

- Polyurethane Belt With Profile

- Special Processing Timing Belt