Polyurethane timing belt splicing process

Polyurethane timing belt uses thermoplastic polyurethane as the belt body and a steel wire core or

Kevlar core as the strength layer. The connection process is not easy to complete. The timing belt

connection process is inseparable from precise design technology and complete equipment support.

It is connected through high-temperature hot melt connection or using plug connection methods.

Barbieri can splice polyurethane timing belts into various lengths and widths according to customer

requirements within processing limits.

1. High temperature hot melt connection method: Jointed timing belt

Use a special timing belt connection mold to engage the two ends of the open timing belt with each

other, install it in the center of the mold, flatten the connection and tighten it, and then put it into the

timing belt connection machine After high-temperature hot-melt die-casting and cooling, the joints

are fused into an annular whole to form an annular timing belt.

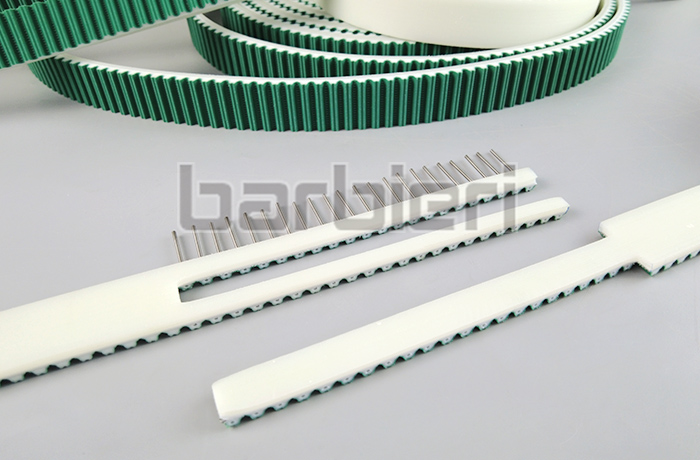

2.Pin splicing method: Pin splice timing belt

Drill holes on the side of the timing belt and fix it with screws and nuts in series. It is also called a latch

to connect the timing belt and a through pin to connect the timing belt. The advantage of the pin-type

spliced timing belt is that it only requires simple tools to quickly connect and install the belt, which is

ideal for reducing machine downtime during replacement and maintenance.

The steel wire is disconnected at the joint of the connecting belt, so the tension at the interface is weaker

than that of the seamless belt. The advantage of connecting the timing belt is that there is no need for

mold restrictions, the length and width can be customized freely, and the degree of freedom is high.

Affordable price, highly favored by customers!

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt