Timing belt skipping teeth phenomenon and its solution

Why does the timing belt skip teeth?

Because the timing belt transmission will produce transmission errors in the process of transmitting motion and power, the timing belt rests on the surface of the tooth profile of the timing pulley, and the cumulative error of N times will make the belt teeth climb to the top circle of the synchronous wheel and slide. teeth, resulting in tooth climbing phenomenon.

cause

1 Frequent starting with impact load may directly cause the synchronous belt teeth to jump out of the synchronous gear slots and climb the teeth.

2 The tension of the timing belt drive is inappropriate.

3 The timing belt drive is overloaded.

4 The timing pulley tooth profile is not on the same plane, and the parallelism error.

5 There is oil on the surface of the timing belt or timing pulley.

How does the timing belt avoid the occurrence of tooth skipping?

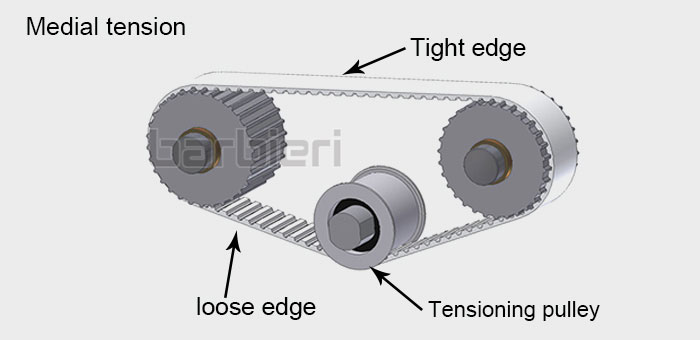

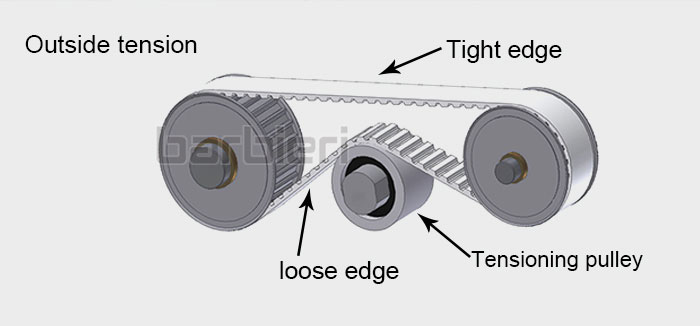

In order to prevent the occurrence of tooth skipping, the synchronous belt should maintain an appropriate tension, improve the overall stiffness of the transmission (especially the bending stiffness of the synchronous wheel shaft), and consider setting up a tensioner if necessary. The factors related to the synchronous belt skip tooth include the friction factor between the synchronous belt and the synchronous wheel, the pitch difference between the synchronous belt and the synchronous wheel, the elastic modulus of the synchronous belt, the tooth profile of the synchronous belt and the synchronous wheel (especially the height of the tooth ) and many more. In addition, under the condition that the length of the tight side of the synchronous belt is constant, lengthening the length of the loose side of the synchronous belt will increase the jumping torque of the synchronous belt. Therefore, the following measures should be taken to avoid tooth skipping:

1 Increase the initial tension.

2 Improve the mechanical rigidity of the equipment.

3 Choose a synchronous belt with high tensile stiffness.

4 Choose a synchronous belt with a larger tooth height.

5 Choose a synchronous belt with a low friction factor.

6 increase the number of teeth of the synchronous wheel.

7 Shorten the center distance of the synchronous wheel

8 Install the tensioner to increase the wrap angle of the synchronous belt.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt